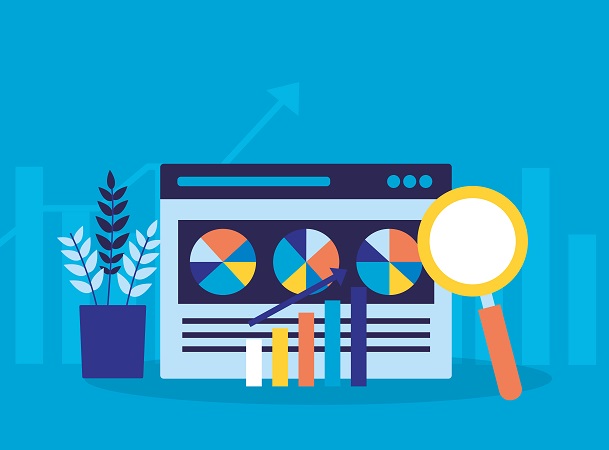

Big data is making big waves in business. By collecting and analyzing massive pools of information, companies can optimize nearly every facet of their business. These data-based solutions make services more profitable for companies and more helpful for customers.

While the most obvious use for big data is in marketing, it can benefit other industries as well. Warehouse inventory management is one such sector that can see noteworthy improvements thanks to this technology.

A well-organized and customer-focused stock is central to the supply chain’s success. Finding ways to improve inventory management is a crucial role of any warehouse manager, and taking advantage of data analytics offers unique ways to improve.

Here are five ways big data can advance warehouse inventory management:

1. Improved Efficiency

Perhaps the most significant advantage big data offers inventory management is in improving efficiency. Warehouse operations include many small, interconnected processes. If just one of them lags, it can cause issues throughout the entire process.

With big data, managers can address efficiency-related problems they may not have known existed. Information collected from the various tools warehouses use can tell administrators if machinery isn’t running at its peak performance. Similarly, data collection can inform supervisors of employee performance and suggest ways to increase productivity.

Poor organization can lead to slowed or faulty operations, just as proper organization can optimize the process. Collecting more information can help managers organize their inventory.

Inventory organization involves both the physical layout of a warehouse and the structure of its operations. Using programs to gather and analyze data within the warehouse as well as information regarding other similar businesses, directors can see where their organization may be lacking.

2. Predicting Needs

One of the most impressive facets of big data is its ability to make accurate predictions. Predicting changes in customer behavior can be a considerable advantage to inventory management.

At different points throughout the year, customers may show entirely different buying habits. If a company can’t see these changes coming, they may find themselves with an inventory full of items they don’t need with no room for what they do need. With the help of big data, they can stock inventories with things that will likely be in demand before they need them too urgently.

While a person can make reasonably accurate predictions, big data may be more trustworthy, as it looks at large pools of hard information. Analytic programs can process far more information in a much shorter time than a person can.

3. Optimized Replenishment

Having too much of a slow-moving item, or not enough of an in-demand one, is a frustrating problem. It can harm both profits and customer satisfaction. Inventory handlers need to take care when replenishing their stock to optimize their shelf space and keep customers happy.

Traditionally, employees have to check inventory manually and decide how much of each item to reorder based on little more than a best guess. Using data to analyze business aspects like sales trends, inventory supervisors can get a much better picture of what they need.

Analytics can reveal if some products are moving off the shelves slowly. They can also alert workers if they’ll need to start ordering more of an item. With both historical sales and trend predictions at their disposal, these analytics can help businesses improve their restocking habits. Incorporating analytics makes inventory management easier.

4. Faster Recalls

Although it’s an unfortunate situation, sometimes companies have to recall certain items. Recalls can be costly and, if handled poorly, can hurt the company’s image, so they need to be fast and effective to minimize damage.

Part of an efficient recall is tracking the items in question. Big data can help with this by tracing products by number and shipment at every step of the supply chain.

Notable retailers like Amazon and Costco use big data to get word of the need for recalls. By monitoring multiple webpages, from review sites to social media, they can get news of potential issues with their products as quickly as possible. By recalling early and taking swift action, companies can significantly reduce the damage caused by these undesirable circumstances.

5. Loss Prevention

Shrinkage happens when inventory records show a higher number of items than what is actually in stock. Shoplifting is the leading cause of inventory shrinkage, but other sources include objects breaking or employees misplacing products.

Data analytics can show if some items tend to go missing at specific times in a particular department. Knowing that this is a place of shrinkage, managers could take further security measures in that area, such as installing cameras to catch thieves. The information would also show if the methods are useful or not by comparing shrinkage levels before and after supervisors take action.

Similar data sets could highlight areas where inventory is inconsistent, showing where employees may be misplacing products.

Changing the Future of Warehouse Inventory With Data Collection

There’s practically no limit to the insights big data can provide to inventory managers, much like in any other industry. By adopting this technology on a broad scale, businesses can meet customer demands more efficiently and increase their revenue.

![7 data-driven ways to optimize your online store for mobile [Infographic]](https://crayondata.ai/wp-content/uploads/2019/11/optimize-1.jpg)

![Top tips and tricks to improving your customer experience [Infographic]](https://crayondata.ai/wp-content/uploads/2019/01/customer-journey-1.jpg)